Aluminum honeycomb cores and panels are becoming key materials in a variety of industries due to their unique structural properties and environmental benefits. Looking ahead, the development trend of aluminum honeycomb products will reshape the landscape of construction, aviation and other industries. This article will delve into the future development trajectory of aluminum honeycomb technology, its applications, and the factors that influence its development.

Understanding Aluminum Honeycomb Structure

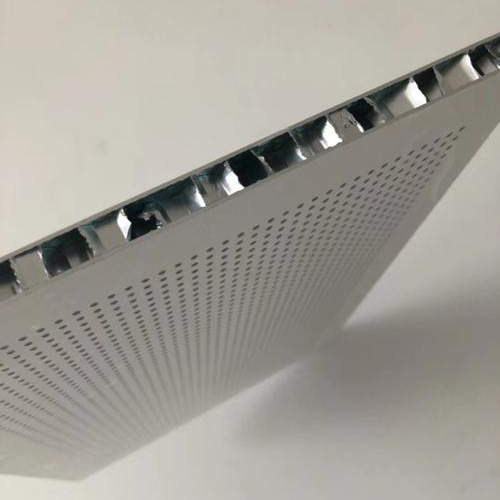

The core of aluminum honeycomb products is the honeycomb sandwich panel, which is made of pure natural hexagonal honeycombs as the core layer. This innovative design not only helps the aluminum honeycomb panel to be lightweight, but also improves its bending stiffness and overall reliability. The unique structure gives it excellent sound insulation and fireproof properties, making aluminum honeycomb panels an ideal choice for a variety of applications from architectural decoration to aerospace manufacturing.

Environmental Benefits and Sustainability

One of the most important trends in the development of aluminum honeycomb products is its alignment with sustainable development goals. Aluminum is a non-radioactive material and is harmless to human health. Its recyclability is a key factor in its appeal, as it can be fully recycled and reused, saving energy and reducing the impact on the environment. As industries pay more and more attention to environmentally friendly materials, aluminum honeycomb is becoming a frontrunner in the search for sustainable building solutions.

Market Potential and Applications

Aluminum honeycomb panels are versatile and can be used in a wide range of fields. In the real estate and architectural decoration sectors, these panels are favored for their aesthetic and functional advantages. The aviation and shipbuilding industries also recognize the advantages of aluminum honeycomb as it is lightweight and helps improve fuel efficiency and performance. With the growing demand for energy-saving and sustainable materials, the market potential of aluminum honeycomb products is expected to expand significantly.

Upstream and downstream market dynamics

The aluminum honeycomb industry has a strong supply chain support. The upstream raw materials include metal aluminum, aluminum honeycomb core, aviation adhesives and machining equipment. The supply of these materials is essential to maintain production levels. However, price fluctuations of raw aluminum and other components affect the overall cost structure of aluminum honeycomb products. As the market develops, stakeholders must navigate these dynamics to ensure profitability and competitiveness.

Innovation in manufacturing process

As the demand for aluminum honeycomb products increases, innovations in manufacturing processes are likely to play a key role in shaping the future of the industry. Technological advances can lead to more efficient production methods, reduce costs and improve product quality. Automation and improved processing techniques can also increase the scalability of aluminum honeycomb manufacturing, allowing companies to meet growing market demands while maintaining high standards.

Regulatory and Safety Considerations

As aluminum honeycomb products gain traction, regulatory and safety considerations will become increasingly important. Compliance with safety standards and environmental regulations will be critical as industries adopt these materials. Manufacturers will need to ensure their products meet strict guidelines in order to gain acceptance in various markets. This focus on safety and compliance will not only protect consumers, but also enhance aluminum honeycomb’s reputation as a reliable and responsible choice.

Future Trends and Predictions

Looking ahead, aluminum honeycomb products have a promising future. According to recent statistics, China’s primary aluminum production is expected to reach 41.594 million tons by 2023, a year-on-year increase of 3.61%. This growth indicates a strong demand for aluminum and its derivatives, including honeycomb products. As industries continue to seek lightweight, durable and sustainable materials, aluminum honeycomb is expected to occupy a considerable market share.

In conclusion

In summary, the future development trend of aluminum honeycomb products is innovation, sustainability and market expansion. As the industry pays more and more attention to environmentally friendly materials and efficient manufacturing processes, aluminum honeycomb panels will play an important role in shaping the future of construction, aviation and other industries. With a strong supply chain, continuous technological advancement and a commitment to safety and compliance, the aluminum honeycomb industry will achieve significant growth in the next few years. As we move forward, stakeholders must remain agile and respond to market dynamics to fully utilize the potential of this extraordinary material.

Post time: Jan-23-2025