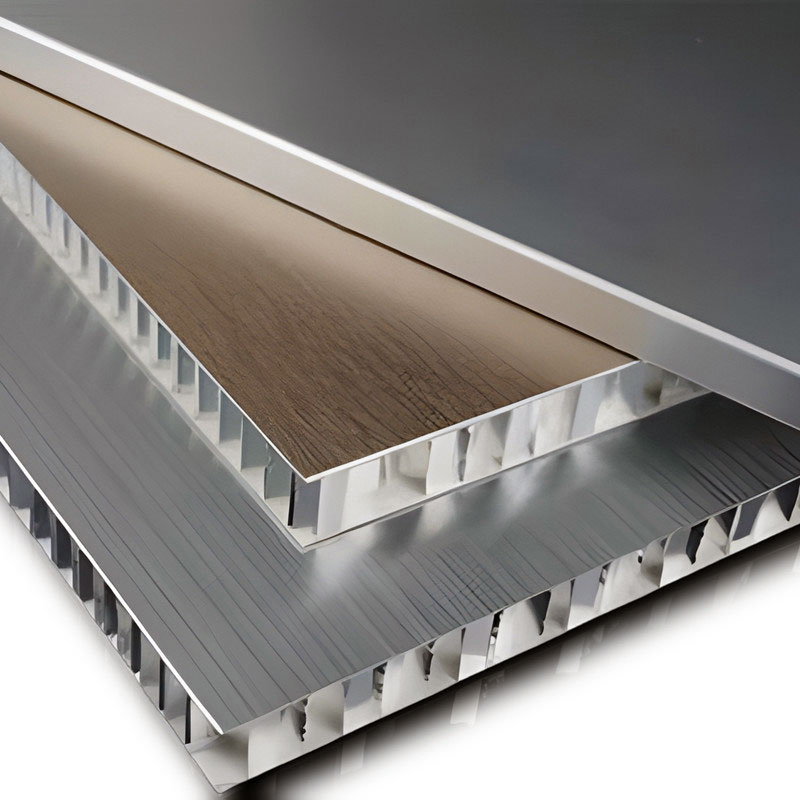

Aluminum honeycomb panel manufacturing process

The manufacture of aluminum honeycomb panels involves a series of complex process steps. First, the aluminum sheet needs to be pre-heated and sanded to prepare for the next step of structural adhesive spraying and heating operations. Then, the honeycomb aluminum core is laid on the treated aluminum sheet, and it is treated with pressure to ensure the stability of the structure. Next, the semi-finished parts are cut and dried, and finally the bonding installation is carried out to complete the manufacturing of aluminum honeycomb panels. In the whole process, it is necessary to be equipped with professional equipment, such as hot press, to ensure production efficiency and product quality.

Aluminum honeycomb panel application field

Aluminum honeycomb panel with its excellent fire and moisture resistance, as well as good sound and heat insulation effects, while both convenient cleaning characteristics, is widely used in a variety of indoor and outdoor environments. It is often used in indoor bathrooms, kitchens, balconies and basements and other damp space ceiling, showing its wide applicability and superior performance.

1.the scope of application of aluminum honeycomb panel

Aluminum honeycomb panel has excellent physical properties and wide applicability, so it is widely used in a variety of occasions. It is not only suitable for structure, cushion, partition and other engineering fields, but also can be used as decorative materials. For example, aluminum honeycomb panels are often used to decorate curtain walls, providing a unique visual effect; At the same time, it is also widely used in building partitions, sound-absorbing panels, suspended ceilings and other projects to play its excellent sound insulation and thermal insulation performance. In addition, the manufacturing of high-speed trains, ships and automobile carriages is also inseparable from the figure of aluminum honeycomb panels, and its convenient cleaning characteristics bring great convenience to the production of these fields.

2.the application of aluminum honeycomb panel in the field of construction

Aluminum honeycomb panels are widely used in the field of construction. It can be used as a decorative material for the outer curtain wall to provide a unique appearance effect for the building. At the same time, it is also used for the construction of internal walls, as well as the decoration of ceilings, adding beauty to the interior space. In addition, aluminum honeycomb panels are often used as metal roofing materials, and their durability and aesthetics are loved by architects and owners. In terms of sound insulation and heat insulation, aluminum honeycomb panels are also excellent, and are widely used in the manufacture of soundproof wall panels and partitions to provide excellent sound insulation for buildings.

Aluminum honeycomb panels play an increasingly important role in the field of architecture because of their unique physical and aesthetic characteristics. It is often used as a decorative material for the exterior curtain wall, bringing a unique appearance effect to the building. In addition, aluminum honeycomb panels are also widely used in the construction of internal walls, as well as the decoration of ceilings, bringing more beauty and comfort to the interior space. At the same time, it is also very popular in the material choice of metal roofing, its durability and beautiful, favored by architects and owners. In terms of sound insulation and heat insulation, aluminum honeycomb panels also show excellent performance, and are often used in the manufacture of sound insulation wall panels and partitions to ensure that the building has excellent sound insulation.

Post time: Jan-21-2025