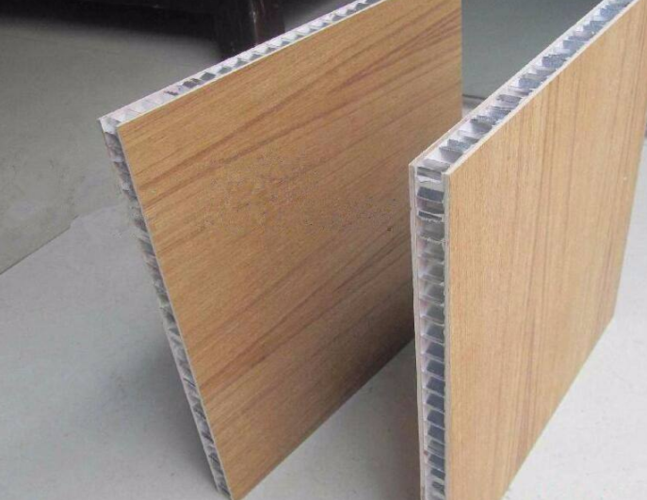

High-pressure laminate (HPL) composite panels are popular in various industries due to their superior performance and versatile applications. The panels are made from a combination of HPL material and honeycomb core, creating a lightweight yet durable structure. Understanding the key properties, advantages and disadvantages of HPL composite panels is critical to making informed decisions regarding their use in different environments.

Principles and performance of HPL composite panels

The key properties of HPL composite panels depend on the combination of materials used in their construction. Known for its high resistance to abrasion, impact and moisture, HPL material forms the outer layer of the panels. This provides excellent protection against external elements, making the panel suitable for both indoor and outdoor applications. Honeycomb cores are typically made from aluminum or thermoplastic materials, helping to make the panels lightweight while maintaining structural integrity.

Advantages of HPL composite panels

1. Durability: HPL composite panels are extremely durable and suitable for high-traffic areas and environments where impact resistance is critical. The HPL outer layer provides superior protection against scratches, abrasions and chemical exposure, ensuring long-term performance.

2. Light weight: The honeycomb core used in HPL panels significantly reduces their weight without compromising strength. This makes the panels easier to handle during installation and reduces the overall load on the structure, making it ideal for applications where weight is a concern.

3. Weather resistance: HPL composite panels exhibit excellent weather resistance, making them suitable for exterior walls, signage and outdoor furniture. HPL materials are able to withstand UV exposure and moisture, ensuring panels maintain their aesthetics and structural integrity over time.

4. Versatility: HPL composite panels are available in a variety of colors, textures, and finishes, allowing for a variety of design options. They can be used in a variety of architectural and interior design applications, including wall cladding, partitions, furniture and decorative elements.

5. Low maintenance: The non-porous surface of HPL board makes it easy to clean and maintain. They are stain-resistant and don’t require a lot of maintenance, making them a cost-effective option in the long run.

Disadvantages of HPL composite panels

1. Cost: While HPL composite panels offer many advantages, they can be relatively expensive compared to other cladding or paneling options. The initial investment required for these panels may prevent some budget-conscious projects from using them.

2. Limited thermal insulation properties: HPL composite panels have limited thermal insulation properties compared to some other building materials. This may affect their suitability for applications where thermal performance is a critical factor.

Application areas and cost advantages

HPL composite panels are widely used in a variety of industries and applications due to their unique combination of properties. Some key use areas and cost advantages include:

1. Building Cladding: HPL composite panels are commonly used for exterior cladding on commercial and residential buildings. Their durability, weather resistance, and aesthetics make them a popular choice for enhancing the visual appeal and protection of a structure.

2. Interior Design: The versatility of HPL panels allows it to be used in interior design applications such as wall panels, partitions and furniture. Its wide range of finishes and textures offer designers the flexibility to create visually appealing and functional spaces.

3. Transportation: HPL composite panels are used in the transportation industry for applications such as vehicle interiors, marine components, and aerospace structures. Their lightweight and durability make them suitable for improving the performance and aesthetics of transport vehicles.

4. Cost advantage: Although the initial cost of HPL composite panels may be higher than some traditional building materials, its long-term cost advantages cannot be ignored. The panel’s low maintenance requirements, long service life and resistance to wear and tear contribute to overall cost savings over its life cycle.

In summary, HPL composite panels offer a unique combination of properties, advantages and disadvantages with their HPL material and honeycomb core structure. Understanding these aspects is crucial to making informed decisions regarding their use in different applications. Despite its limited initial cost and insulating properties, durability, lightness, weather resistance, versatility and long-term cost advantages make HPL composite panels a compelling choice for a variety of construction, interior design and transportation applications. As technology and materials continue to advance, HPL composite panels may remain an important option for innovative and sustainable building solutions.

Post time: Sep-03-2024