Los Angeles, CA - 3003 Aluminum Honeycomb Core Panels are becoming increasingly popular as a lightweight and versatile material that can be used as an alternative to heavier steel panels. 3003 aluminum honeycomb core has a variety of applications, particularly in the aerospace and construction industries. This breakthrough material offers enhanced strength, durability and weight efficiency, making it an attractive choice for a variety of projects.

The 3003 aluminum honeycomb core panel is composed of hexagonal units connected to each other to form a honeycomb structure. This design provides an excellent strength-to-weight ratio, making it ideal for applications where weight reduction is critical. Additionally, this aluminum honeycomb core offers excellent corrosion resistance, making it an excellent choice for outdoor applications and structures exposed to harsh environments.

One of the main advantages of 3003 aluminum honeycomb core is its excellent weight-saving properties. Compared to traditional steel panels, 3003 aluminum honeycomb core panels are significantly lighter, without compromising strength and durability. The reduced weight of these panels brings positive impacts such as reduced transportation costs and structural requirements.

The aerospace industry has greatly benefited from the use of 3003 aluminum honeycomb core panels. These panels are used in aircraft interiors to create lightweight yet strong structures for cabin partitions, galleys and overhead compartments. In addition, the corrosion-resistant properties of 3003 aluminum honeycomb core make it suitable for aircraft exteriors, increasing durability against environmental factors.

In the construction industry, 3003 aluminum honeycomb core panels are often used as internal and external cladding materials for high-rise buildings. Their lightweight nature simplifies installation and reduces loads on the supporting structure. In addition, the excellent fire resistance of 3003 aluminum honeycomb core panels has further increased its demand in the construction field.

This innovative material is also sought after for its excellent sound and thermal insulation properties. The hexagonal cells of the 3003 aluminum honeycomb core panel effectively trap air, significantly reducing sound transmission. Additionally, the air pockets within the honeycomb structure act as thermal insulators, helping to create energy-efficient spaces.

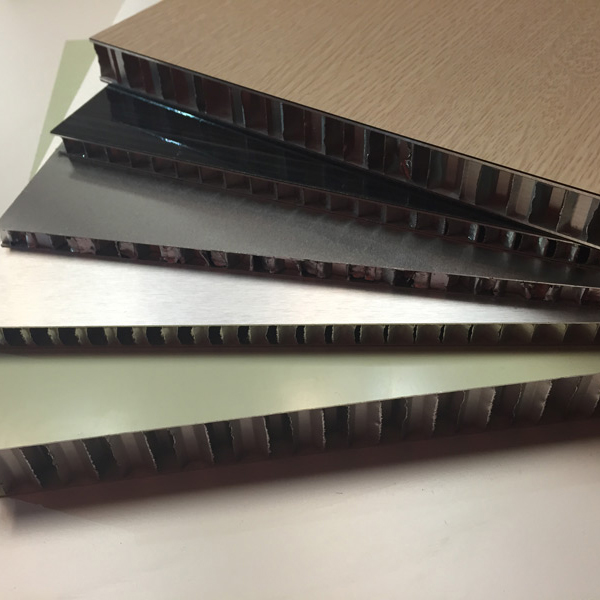

In order to meet the different requirements of different applications, 3003 aluminum honeycomb core panels are available in a variety of thicknesses and sizes. This enables architects, engineers and designers to select the most appropriate panel size to meet specific project needs. The material's versatility makes it an attractive choice for new construction and retrofit applications.

As the demand for lightweight and durable materials continues to grow, 3003 aluminum honeycomb core panels offer a promising solution. Its remarkable features such as weight reduction, corrosion resistance, fire protection, sound insulation, and heat insulation make it the first choice in aerospace, construction and other industries. With the continuous progress of research and development, it is expected that the application possibilities of 3003 aluminum honeycomb core panels will be further expanded, which will bring revolutionary changes to various industries in the future.

Post time: Nov-21-2023