-

Commercial Grade Aluminum Honeycomb Core Manufacturer

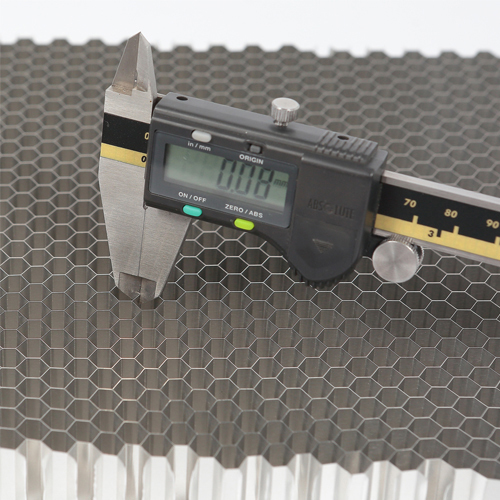

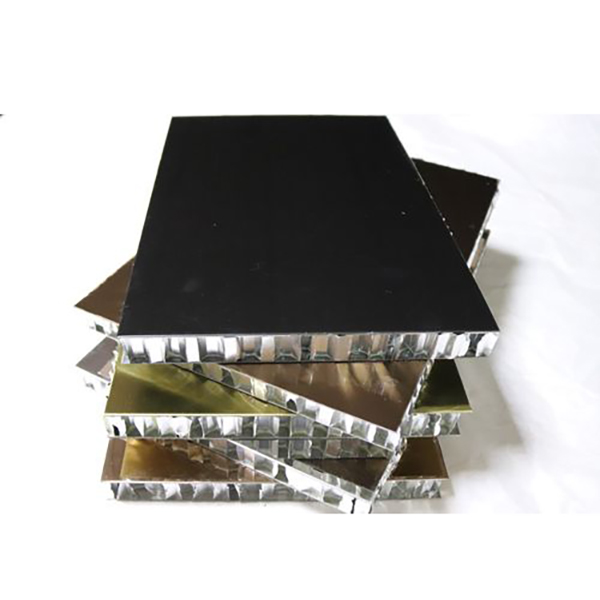

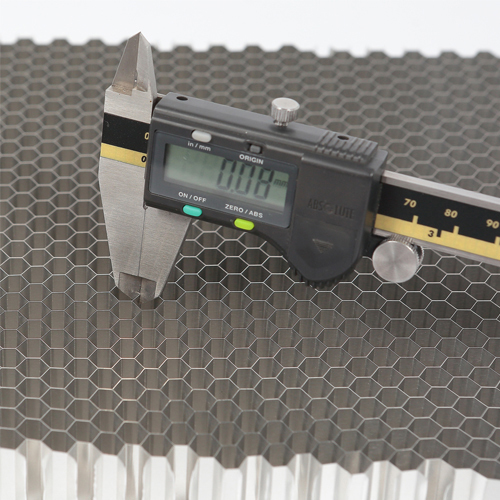

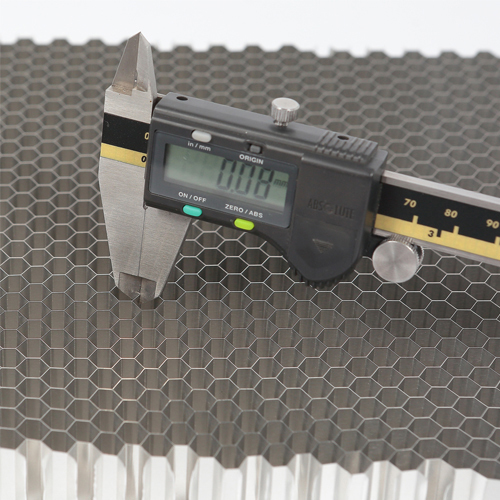

The aluminum honeycomb core is composed of multiple layers of aluminum foil adhesive, forming a regular hexagonal structure. The resulting hole walls are sharp, clear and burr-free, ensuring high-quality bonding and material integrity. The hexagonal aluminum honeycomb structure contains a dense wall beam configuration that provides even pressure distribution across the entire panel and maintains high flatness even over large areas. In addition, the hollow honeycomb design effectively reduces thermal expansion. Our product range includes monolithic, sliced, expanded, perforated and etched honeycomb options to suit different needs.

-

Honeycomb Core Sandwich Panels Aluminum Toilet Partition Manufacturer

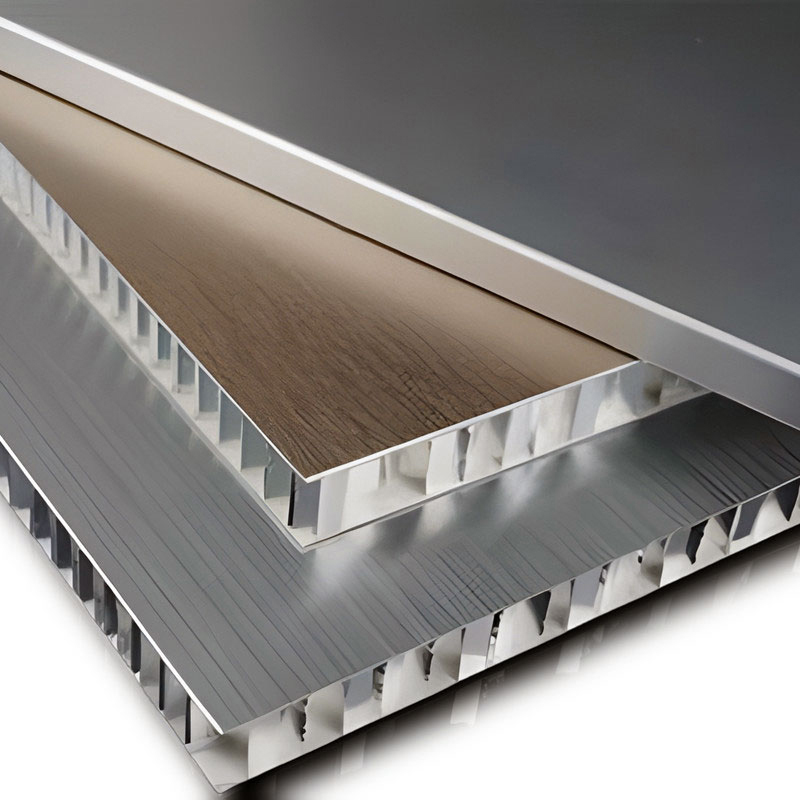

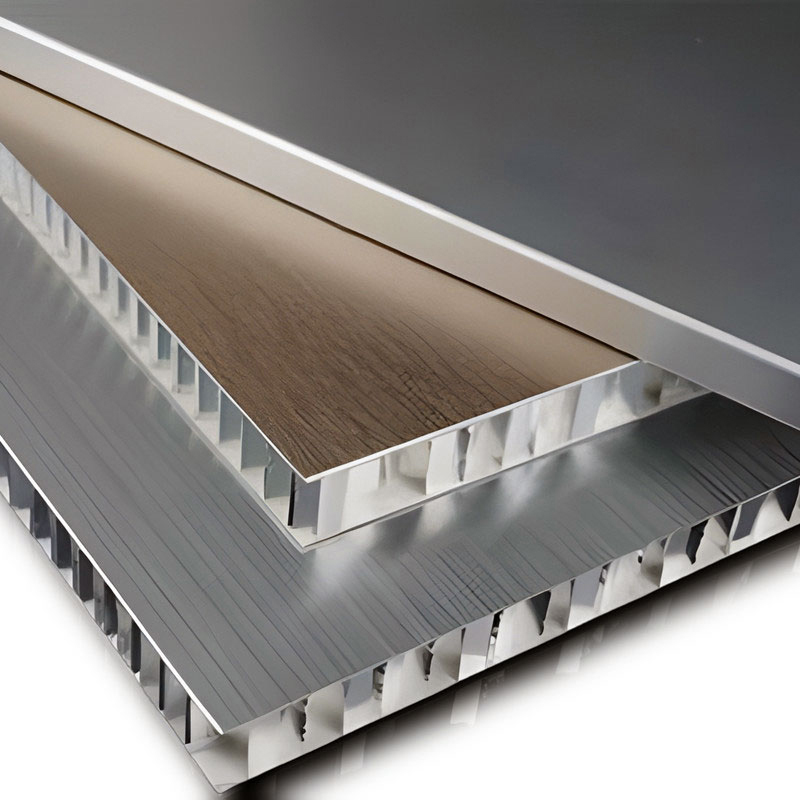

Introducing our high quality honeycomb aluminum panels, also known as aluminum honeycomb core panels. This composite material is widely recognized for its superior product performance and is highly sought after by high-end construction companies in the industry. The board is known for its exceptional strength, resisting bending and ensuring a high level of flatness. Its ease of installation adds to its appeal, making it a favorite for construction projects.

One of the key features of our aluminum honeycomb panels is their excellent strength-to-weight ratio, making them an ideal solution for a variety of projects. Its application fields continue to expand and it has established a strong influence in the construction market.

Our Cheonwoo honeycomb core and honeycomb panel engineering technology ensures precise product parameters, backed by IOS certification and IMDS data. Our team also provides professional drawing and analysis to resolve any technical issues, and we have extensive experience in multiple fields. We are committed to providing the highest quality solutions and excellent customer service.

Whether you are looking for a durable, high-strength material for your construction project or need a reliable solution for a specific application, our honeycomb aluminum panels are the perfect choice. Contact us today to discuss your specific requirements and discover the many benefits our products have to offer. With our expertise and industry-leading products, we are confident that we can provide the perfect solution for your needs.

-

Light Aluminum Honeycomb Panel Impact Resistant for Vehicle Interiors

Aluminum honeycomb panels are becoming increasingly popular in the construction industry due to their excellent product properties. These composite materials are known for their high strength, impact resistance and versatility, making them the perfect solution for a variety of projects. In fact, high-end construction companies are increasingly using these panels in vehicle interiors due to their exceptional durability and stability.

One of the main advantages of aluminum honeycomb panels is their ability to withstand high impact forces. This is especially important for car interiors, whose panels are often subject to heavy wear and tear. Whether for floors, walls or ceilings, these panels provide superior impact protection and ensure the safety and longevity of interior surfaces.

Aluminum honeycomb panels are also known for their high strength and rigidity. They resist bending and are highly flat, making them ideal for interior paneling. In addition, its excellent strength-to-weight ratio makes it a lightweight and extremely durable automotive interior solution, achieving the perfect balance between performance and efficiency.

Aluminum honeycomb panels are very easy to install, saving construction time and costs. Their ease of installation means they can be quickly and seamlessly integrated into a variety of vehicle interior applications, further enhancing their appeal to construction companies and designers.

As the application areas of aluminum honeycomb panels continue to expand, their reputation in the construction market has long been established. Offering excellent impact resistance, high strength and ease of installation, these panels are an excellent choice for any project, including vehicle interiors. Whether you are working on a commercial or residential construction project, these panels can provide the durability and reliability your interior surfaces require.

-

Wholesale Aluminum Honeycomb Acoustic Panels for Railway Carriage

1) Decoration material: aluminum honeycomb curtain wall composite board

2) Household appliances: air purifier grille

3) Lighting industry: all kinds of lighting, traffic light barriers

4) Audio industry: headphones, speakers, etc.

5) Transportation industry: decorative materials such as carriages, train doors, partitions, etc.

6) Furniture industry: office furniture, display furniture

-

4×8 Honeycomb Marble Panels with Aluminum Core Factory

Introducing our revolutionary building material – Honeycomb Marble Slabs. This innovative product is a combination of aluminum honeycomb panels and composite marble panels that offer unparalleled strength, durability and aesthetics.

The aluminum honeycomb panel used in our honeycomb marble panels is a lightweight yet extremely strong material. It has excellent thermal insulation, fire protection and earthquake resistance properties, making it ideal for a variety of building applications. Additionally, its lightweight nature makes it easy to handle and install, reducing labor and installation costs.

Composite marble panels are equally impressive, offering the natural beauty of marble with the durability and ease of maintenance of synthetic materials. This decorative material is made by mixing marble particles with synthetic resin, creating a stunning finish that can elevate any space. Composite marble panels are available in a variety of colors and patterns, offering endless design possibilities.

By combining these two special materials, our Honeycomb Marble Panels offer the best of both worlds. Not only do they have the strength and functionality of aluminum honeycomb panels, but they also add a touch of elegance and sophistication to the beauty of composite marble. Whether used for interior decoration, exterior cladding or furniture design, these panels are sure to impress.

In addition to strength and beauty, honeycomb marble slabs are also environmentally friendly. The use of lightweight materials reduces the building’s carbon footprint, while the durability of the panels ensures a long service life, minimizing the need for replacement and reducing waste.

All in all, honeycomb marble slabs are a game changer for the construction and design industry. They offer a unique combination of strength, beauty and sustainability, making them the perfect choice for any project. Whether you are an architect, designer or builder, our honeycomb marble slabs are guaranteed to exceed your expectations.

-

Light Honeycomb Marble Panels Supplier High Strength

The use of metal detectors by food companies has become an indispensable part of ensuring product quality and safety. With increasing consumer awareness and stringent regulations, food manufacturers are actively implementing preventive measures to prevent metal contamination in their products. A crucial step is to install metal detectors throughout the production process, from raw material storage to packaging. Metal detectors are used at various stages of food production to identify and eliminate any metal contaminants that may enter the process. They are particularly useful in raw material storage areas, where raw materials are stored before being used on the production line. Metal detectors can quickly scan raw materials for any metal fragments or foreign objects that may have gotten in during transportation or storage. By detecting and removing these contaminants at an early stage, companies can further prevent potential problems. During the production process, metal detectors are used to inspect products at different stages. This ensures that any metal contaminants or foreign objects accidentally introduced during processing are promptly identified and removed. Metal detectors can detect even the smallest metal particles, helping to maintain the integrity and safety of the final product. There are many benefits to installing metal detectors in food establishments. First, it can detect and remove metal contaminants before they reach consumers, helping to prevent costly product recalls. This not only allows the company to avoid financial losses, but also protects its brand reputation.

-

Marble Aluminum Honeycomb Composite panels Supplier

Aluminum Honeycomb Panel + Composite Marble Panel is a unique fusion of high-quality materials, combining the lightweight, high-strength properties of aluminum honeycomb with the natural beauty and durability of composite marble. Aluminum honeycomb panels offer excellent thermal insulation, fire protection and earthquake resistance, while composite marble panels offer the elegant beauty of marble with the durability and low maintenance of synthetic materials. By bringing these two panels together, the final combination leverages the strengths of each material to create a versatile and reliable building solution.

-

Metal Honeycomb Panel for Wall Cladding

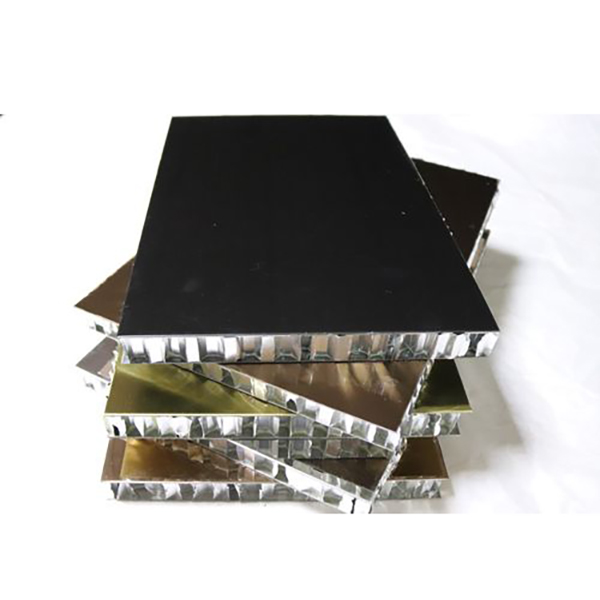

The metal honeycomb panel is made of high-quality materials including metallic mirror aluminum, stainless steel and other high-quality components. Designed specifically for interior decoration, it is ideal for enhancing the beauty of various environments, such as shopping mall elevators, hotel designs and other decorative applications. Metallic mirror aluminum not only adds luxury and modernity, but also offers excellent corrosion resistance. The combination of stainless steel and other composite materials enhances the overall durability and stability of the panels, ensuring a high-quality and long-lasting structure.

-

Wholesale Metal Honeycomb Sheet for Interior Decoration

Metal Honeycomb Panel is ideal for enhancing the beauty of a variety of environments, such as shopping mall elevators, hotel designs and other decorative applications.Our metal honeycomb panels are made from top-notch materials including metallic mirror aluminum, stainless steel and other high-quality components. The use of metallic mirrored aluminum not only adds a luxurious and contemporary feel to any space, but it also offers excellent corrosion resistance, ensuring the panels remain in pristine condition for years to come. It’s lightweight and easy to install, while its sturdy construction ensures it will stand the test of time.

-

Composite Variety Plates with Aluminum Honeycomb Core Supplier

Introducing our latest product, aluminum honeycomb panel. Our aluminum honeycomb panels are made by superimposing multiple layers of aluminum foil adhesive and then stretched into a regular hexagonal honeycomb core. The cell walls of the aluminum honeycomb core are sharp and clear without any burrs, making it suitable for high-quality bonding and other purposes. The core’s hexagonal aluminum honeycomb structure contains dense honeycomb wall beams that can withstand pressure from the other side of the panel, ensuring even force distribution.

Our aluminum honeycomb panels are ideal for a wide range of applications, including as adhesively bonded core materials, construction materials and for use in the manufacture of lightweight yet strong composite panels. With their strong and durable construction, our aluminum honeycomb panels are ideal for use in a variety of industries, including aerospace, marine, automotive and architectural design.

Aluminum honeycomb panels are designed to provide an excellent strength-to-weight ratio, making them an ideal material for applications where weight is a critical factor. The honeycomb structure of the core ensures that the panel can withstand high levels of pressure and force, making it a reliable and long-lasting solution for a variety of applications.

In addition, the aluminum structure of the honeycomb panel ensures that it is corrosion-resistant and suitable for use in both indoor and outdoor environments. The versatility and durability of our aluminum honeycomb panels make it a cost-effective and practical solution for a variety of applications.

Whether you need lightweight yet strong building materials, bonded materials or composite panels, our aluminum honeycomb panels are the perfect choice. Trust the quality and reliability of our aluminum honeycomb panels to meet all your project needs.

-

Corrosion Resistant Aluminum Honeycomb Core Manufacturer Building Material

Introducing our latest product, the Aluminum Honeycomb Core. This innovative material is made up of layers of aluminum foil adhesive, overlying, and then stretched into a regular hexagonal honeycomb core. The hole wall of the aluminum honeycomb core is sharp, clear, and without burrs, making it suitable for high-quality adhesive and other purposes. The hexagonal aluminum honeycomb structure of the core layer contains dense honeycomb-like many wall beams, enabling it to bear pressure from the other side of the panel. This results in uniform force distribution across the panel, making it ideal for applications requiring strength and stability.The versatility of the Aluminum Honeycomb Core makes it a valuable material for various industries. It can be used in construction for lightweight and high-strength composite panels. In transportation, it can be applied to create lightweight and durable vehicle components. Additionally, it can be utilized in furniture and interior design to achieve a balance between strength and weight.One of the key benefits of using Aluminum Honeycomb Core is its exceptional strength-to-weight ratio. The honeycomb structure provides excellent structural support while keeping the overall weight at a minimum. This makes it an ideal choice for applications where weight reduction is a priority without compromising on durability and performance. Furthermore, the aluminum material offers corrosion resistance, ensuring longevity and durability in various environmental conditions. This makes the Aluminum Honeycomb Core a reliable choice for both indoor and outdoor applications. Overall, the Aluminum Honeycomb Core offers a powerful combination of strength, lightweight construction, and versatility, making it an excellent choice for a wide range of industrial and commercial applications. Whether you are looking for reliable construction materials or innovative design solutions, the Aluminum Honeycomb Core is sure to meet and exceed your expectations.

-

Perforated Sound Absorption Coated Aluminum Honeycomb Panels Supplier

1. After determining the form of the interior facade or ceiling, cooperate with the manufacturer to determine the material selection and form of the keel

2, there are a variety of shapes and functions, the shape is divided into strip plate type, block plate type and various special-shaped plates

3, installation side and non-installation side can be used in combination

4, each board can be disassembled and replaced separately, easy to install and maintain the facilities in the wall and ceiling

5, for the installation of lamps, shower heads and air conditioning openings can be machined in the factory

6. Scope of application