Application

1.Sound insulation, Heat preservation:

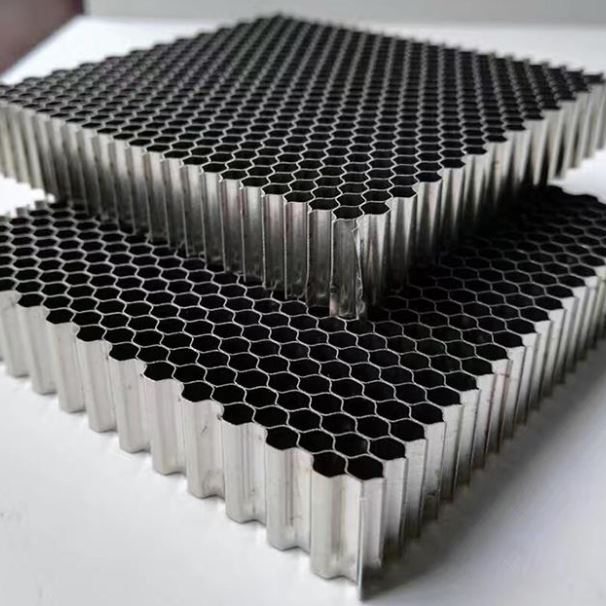

The material has good sound insulation and thermal insulation performance because the air layer between the two layers of plates is separated into multiple closed pores by honeycomb, so that the transmission of sound waves and heat is greatly limit

2.Fire prevention:

After the inspection and appraisal of the national fire prevention building materials Quality supervision and inspection center, the performance index of the material is in line with the requirements of the fire retardant material. According to the specification of GB-8624-199, the combustion performance of the material can reach GB-8624-B1 level.

3.Superior flatness and rigidity:

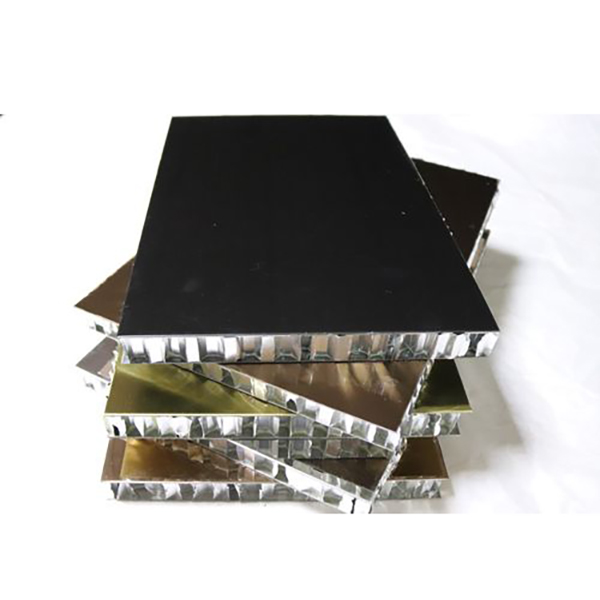

Aluminum honeycomb plate has a lot of mutual control of dense honeycomb composition, like many small I-beam, can be dispersed under the pressure from the direction of the panel, so that the panel force is uniform, to ensure the strength of the pressure and the large area of the panel to maintain a high flatness.

4.Moisture-proof:

The surface adopts the pre-rolling coating process, anti-oxidation, no discoloration for a long time, no mildew, deformation and other conditions in the humid environment.

5.Light weight, Energy conservation:

The material is 70 times lighter than a brick of the same size and only one-third the weight of stainless steel.

6.Environment protection:

The material will not emit any harmful gaseous substances, easy to clean, recyclable and reused.

7.Anticorrosion:

There is no change after inspection in 2% HCL in solution soaking for 24 hours, and in saturated Ca(OH)2 solution soaking also.

8.Construction convenience:

Products have matching alloy keel, easy to install, save time and labor; Repeatable disassembly and migration.

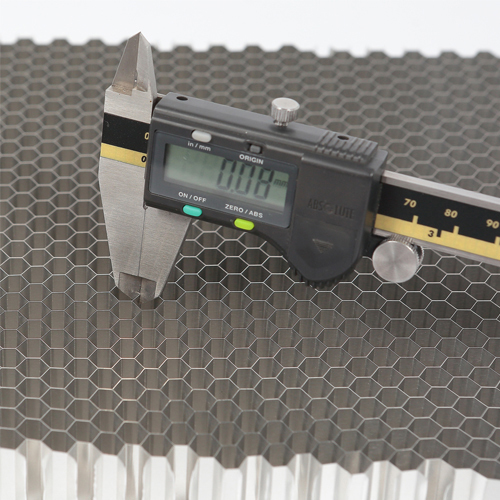

Specifications

Honeycomb core of Density and Falt compressive strength.

|

Honeycomb Core Foil Thickness/Length(mm) |

Density Kg/ m² |

Compressive Strength 6Mpa |

Remarks |

|

0.05/3 |

68 |

1.6 |

3003H19 15mm |

|

0.05/4 |

52 |

1.2 |

|

|

0.05/5 |

41 |

0.8 |

|

|

0.05/6 |

35 |

0.7 |

|

|

0.05/8 |

26 |

0.4 |

|

|

0.05/10 |

20 |

0.3 |

|

|

0.06/3 |

83 |

2.4 |

|

|

0.06/4 |

62 |

1.5 |

|

|

0.06/5 |

50 |

1.2 |

|

|

0.06/6 |

41 |

0.9 |

|

|

0.06/8 |

31 |

0.6 |

|

|

0.06/10 |

25 |

0.4 |

|

|

0.07/3 |

97 |

3.0 |

|

|

0.07/4 |

73 |

2.3 |

|

|

0.07/5 |

58 |

1.5 |

|

|

0.07/6 |

49 |

1.2 |

|

|

0.07/8 |

36 |

0.8 |

|

|

0.07/10 |

29 |

0.5 |

|

|

0.08/3 |

111 |

3.5 |

|

|

0.08/4 |

83 |

3.0 |

|

|

0.08/5 |

66 |

2.0 |

|

|

0.08/6 |

55 |

1.0 |

|

|

0.08/8 |

41 |

0.9 |

|

|

0.08/10 |

33 |

0.6 |

Conventional size specifications

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

|

1/8" |

|

|

3/16" |

|

1/4" |

|

|

|

mm |

2.6 |

3.18 |

3.46 |

4.33 |

4.76 |

5.2 |

6.35 |

6.9 |

8.66 |

|

|

Side |

mm |

1.5 |

1.83 |

2 |

2.5 |

2.75 |

3 |

3.7 |

4 |

5 |

|

Fiol thickness |

mm |

0.03~0.05 |

0.03~0.05 |

0.03~0.05 |

0.03~0.06 |

0.03~0.06 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

Width |

mm |

440 |

440 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Length |

mm |

1500 |

2000 |

3000 |

3000 |

3000 |

4000 |

4000 |

4000 |

5500 |

|

High |

mm |

1.7-150 |

1.7-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

||||||||||

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

3/8" |

|

1/2" |

|

|

3/4" |

|

1" |

|

|

mm |

9.53 |

10.39 |

12.7 |

13.86 |

17.32 |

19.05 |

20.78 |

25.4 |

||

|

Side |

mm |

5.5 |

6 |

|

8 |

10 |

11 |

12 |

15 |

|

|

Fiol thickness |

mm |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

|

Width |

mm |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

|

Length |

mm |

5700 |

6000 |

7500 |

8000 |

10000 |

11000 |

12000 |

15000 |

|

|

High |

mm |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

|

||||||||||

|

1.Also we can customize according to the demand of clients |

||||||||||

-

Wholesale Metal Honeycomb Sheet for Interior De...

-

Waterproof Public Toilet Cubicle Partition Pane...

-

Honeycomb Core Sandwich Panels Aluminum Toilet ...

-

Durable Custom Laminated Honeycomb Panel Manufa...

-

Sound-absorbing Aluminum Honeycomb Panel for Sale

-

Commercial Grade Aluminum Honeycomb Core Manufa...